Steel crank-up self-supporting towers

| Description | Tower height in fully unfolded position, max., m | Tower height with fixed turbular section, m | Tower height in folded (transport) position, m | Number of Sections | Bottom section horizontal size, mm | Top section horizontal size, mm | Tower weight, kg |

| Section length 3 m | |||||||

| CT-S3-3-3000 | 8.0 | 10.0 | 3.4 | 3 | 408 | 200 | 198 |

| CT-S3-4-3000 | 10.5 | 12.5 | 3.6 | 4 | 512 | 200 | 288 |

| CT-S3-5-3000 | 13.0 | 15.0 | 3.8 | 5 | 616 | 200 | 388 |

| CT-S3-6-3000 | 15.5 | 17.5 | 4.0 | 6 | 720 | 200 | 504 |

| Section length 3 m, reinforced | |||||||

| CT-S3-3X-3000 | 8.0 | 10.0 | 3.4 | 3 | 512 | 304 | 240 |

| CT-S3-4X-3000 | 10.5 | 12.5 | 3.6 | 4 | 616 | 304 | 338 |

| CT-S3-5X-3000 | 13 | 15.0 | 3.8 | 5 | 720 | 304 | 455 |

| Section length 3.5 m | |||||||

| CT-S3-3-3500 | 9.5 | 11.5 | 3.9 | 3 | 408 | 200 | 232 |

| CT-S3-4-3500 | 12.5 | 14.5 | 4.1 | 4 | 512 | 200 | 337 |

| CT-S3-5-3500 | 15.5 | 17.5 | 4.3 | 5 | 616 | 200 | 452 |

| CT-S3-6-3500 | 18.5 | 20.5 | 4.5 | 6 | 720 | 200 | 589 |

| Section length 3.5 m, reinforced | |||||||

| CT-S3-3X-3500 | 9.5 | 11.5 | 3.9 | 3 | 512 | 304 | 280 |

| CT-S3-4X-3500 | 12.5 | 14.5 | 4.1 | 4 | 616 | 304 | 395 |

| CT-S3-5X-3500 | 15.5 | 17.5 | 4.3 | 5 | 720 | 304 | 531 |

| Section length 5 m | |||||||

| CT-S3-2-5000 | 9.2 | 11.2 | 5.2 | 2 | 304 | 200 | 231 |

| CT-S3-3-5000 | 13.4 | 15.4 | 5.4 | 3 | 408 | 200 | 331 |

| CT-S3-4-5000 | 17.6 | 19.4 | 5.6 | 4 | 512 | 200 | 481 |

| CT-S3-5-5000 | 21.8 | 23.8 | 5.8 | 5 | 616 | 200 | 646 |

| CT-S3-6-5000 | 26.0 | 28.0 | 6.0 | 6 | 720 | 200 | 841 |

| Section length 5 m, reinforced | |||||||

| CT-S3-2X-5000 | 9.2 | 11.2 | 5.2 | 2 | 408 | 304 | 249 |

| CT-S3-3X-5000 | 13.4 | 15.4 | 5.4 | 3 | 512 | 304 | 399 |

| CT-S3-4X-5000 | 17.6 | 19.4 | 5.6 | 4 | 616 | 304 | 564 |

| CT-S3-5X-5000 | 21.8 | 23.8 | 5.8 | 5 | 720 | 304 | 759 |

CT-S3-xx series Crank-up steel self-supporting towers is a Communication Technologies unique solution for stationary and rapid mobile deployment of heavy and super-heavy HF-antennas, lighting systems and cellular base station’s (BTS) antennas.

Tower sections are steel triangular-shape hot-dip galvanized constructions with 200, 300, 400, 500, 600,700 mm side width and 3, 3,5 or 5 m length. Section’s vertical legs are made of high strength seamless steel tubing with 40 mm outer dia. and wall thickness of 4 – 6 mm. Horizontal braces are made of serpentine Z-shaped structures of 18 mm circle and 14 x 4 mm tubing.

Tower height in fully unfolded position is 8 to 28 m depending on the chosen configuration (3,3 m to 5,75 m in assembled or folded (transport) position).

Max. equipment load at 26 m Tower height top:

- self-supporting Tower applications — 200 kg max.;

- guyed-Tower applications — 400 kg max.

Required deployment area:

- self-supporting Tower applications — 2x2 m square;

- guyed-Tower applications — 5 to 15 m dia. сircle.

Based on installation options, tower top sectioned may be provided in 3 different configurations:

|

|

|

| Section with Mounting Plate | Section with Mast | Section with Basket |

In stationary application, the tower is installed on a pre-prepared concrete foundation with an integrated hinged base for lifting up from a horizontal state. Foundation calculation is made based on a selected tower structure model and planned equipment to be installed . Tower installation is not a time-consuming procedure as it is shipped in a fully assembled condition, taking into account that, depending on the tower weight and size, machinery use may be required.

For mobile application, either a hinged mount fixed on the ground or mount to the vehicle body may be used, depending on tower height and total weight. To reduce the load on the tower base, a tier of guy wires may be used.

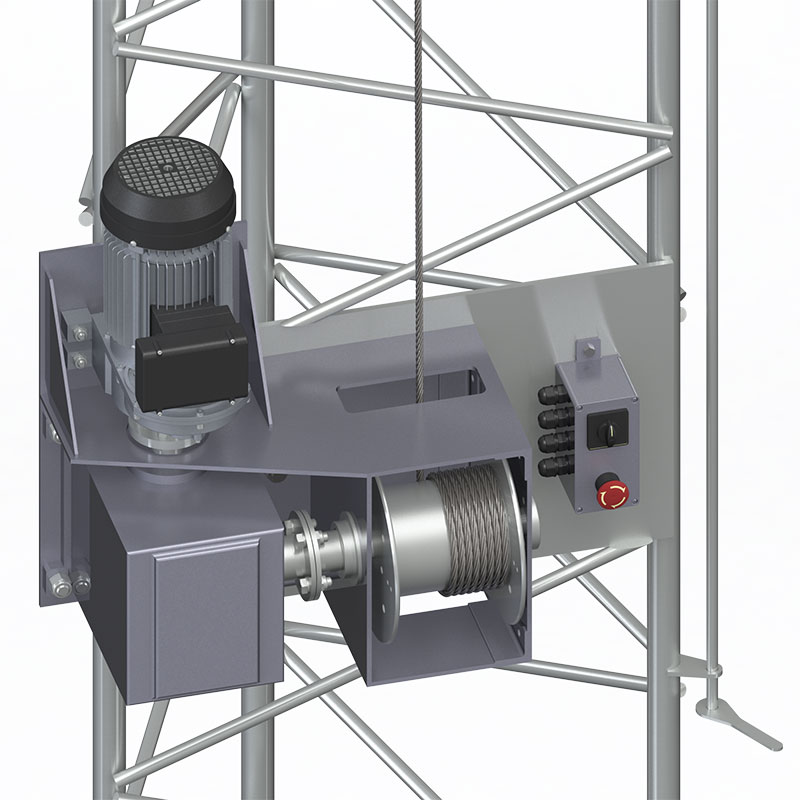

All CT-S3xx series towers are equipped with mechanical erection systems (i.e. mechanical winches) installed on the lowest section. At the Customer's discretion, the mechanical system can be replaced by an electrical one. Required deployment time to put tower from the assembled state to the full operational height does not exceed 5-10 mins.

|

|

|

| Mechanical erection system | Electric erection system up to 300 kg (gear drive shown without protective cover) | Electric erection system up to 1000 kg (gear drive shown without protective cover) |

Since Steel Crank-up Self-supporting Towers have a wide range of applications, options for mounting antenna and other equipment are agreed with the Customer at the stage of order formation.